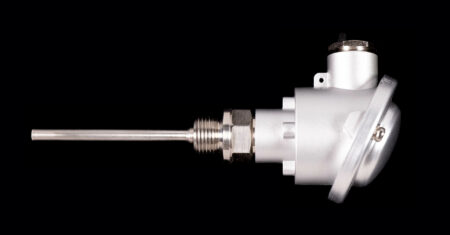

Sheathed thermocouples with a tapered measuring point are our answer to the question of short response times but stable and resilient processing or when, for example, threaded holes require a taper due to their design. Only one end of the thermocouple, including the measuring point, is reduced in diameter so that it remains extremely robust overall and can be ideally inserted into holes or threads using welding sleeves or through-bore fittings.

The tapering of thermocouples is possible up to an outer diameter of 0.5 mm. The diameter of a thermocouple can be reduced by up to 50% of the original diameter. New: It is also possible to reduce the outer diameter in several steps, e.g. from 2mm to 1mm and then to 0.5mm. The length of the thermocouple as well as the length of the tapered section can also be selected individually - depending on the application.

We also offer various versions of measuring points. For applications in the high-frequency range, for example, we recommend an insulated measuring point (IMV): An insulating layer (e.g. MgO) encloses the measuring point and prevents the connection to the sheathed cable. In this way, the measuring point is protected from mechanical stress and direct contact with environmental influences - and important to know: Compared to sheath-welded measuring points, leakage currents are significantly reduced.

We always deliver precision work by hand, because we understand your problem and our craft. Our sheathed thermocouples are manufactured on the basis of mineral-insulated sheathed cables. Production and design are in accordance with DIN EN 60584.

On request, we can also supply your sheathed thermocouples ready assembled with a thermocouple cable and/or thermocouple plug.