Typical application examples for sheathed thermocouples

Sheathed thermocouples, also known as sheathed thermocouples, are used in various industries and applications where precise temperature measurements are required. This type of thermocouple consists of two different metallic conductors that are connected at one end and open at the other. The open ends are placed at the location where the temperature is to be measured. ThermoExpert° Deutschland GmbH, with its managing directors Heiko Gevert and Andreas Helf, has been a partner to all these branches of industry and research for many years. The range of applications for thermocouples is almost unlimited - as is the wealth of ideas for helping customers achieve their goals.

Heating solutions from ThermoExpert

In this short film, you can see the heating of a customer-specific heating solution in fast motion. The required final temperature is reached extremely evenly and to the point - constantly and precisely monitored by our jacket thermocouples from our own production. With our team in Stapelfeld, we have been successfully implementing even the most complicated or complex requirements for many years - from minimal heating capacities to heating plates or surfaces with several kW output. Our clients can be found in research and education, the food industry, aerospace, the automotive sector and so on.

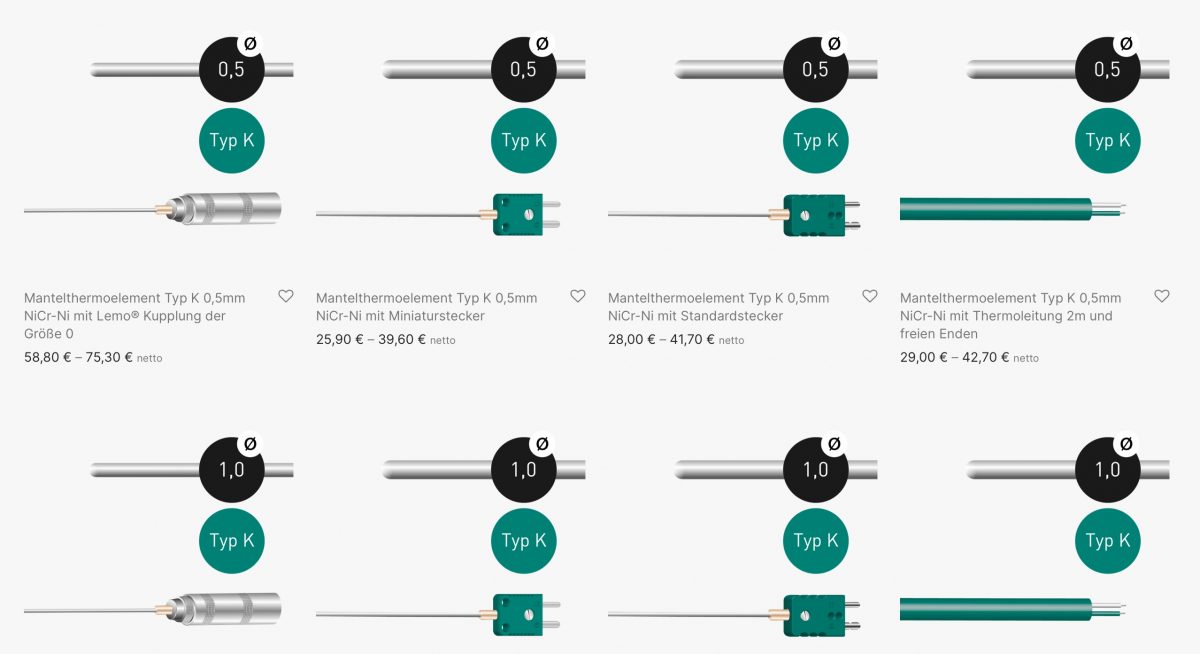

New: Shop for sheathed thermocouples

As you know, the ThermoExperts are specialists for all topics relating to heating, temperature measurement and the generation of temperatures - in addition, we now offer the option of ordering the required thermocouples quickly and easily online in our online store [ Thermoelement.store ] for standard items that are always in demand. Here you will find thermocouples of types K, J, N and L. Sensor length and sheath materials can be easily selected via dropdown - immediate production of your order here in Stapelfeld is of course guaranteed - as always, the TE° team looks forward to receiving your orders.

Sheathed thermocouple or PT 100 - a comparison and overview of the differences

In order to measure temperatures accurately, reproducibly and with long-term stability, platinum resistance thermometers (PT100) can be used in addition to sheathed thermocouples. To make the right choice, it is important to check your requirements in terms of accuracy, long-term stability and temperature range, as well as the ambient conditions. ThermoExpert GmbH has been advising its customers for over 10 years and finds a technical solution for every challenge. We would be happy to advise you too - contact us at any time, e.g. via our chat function on the thermoexpert.de website

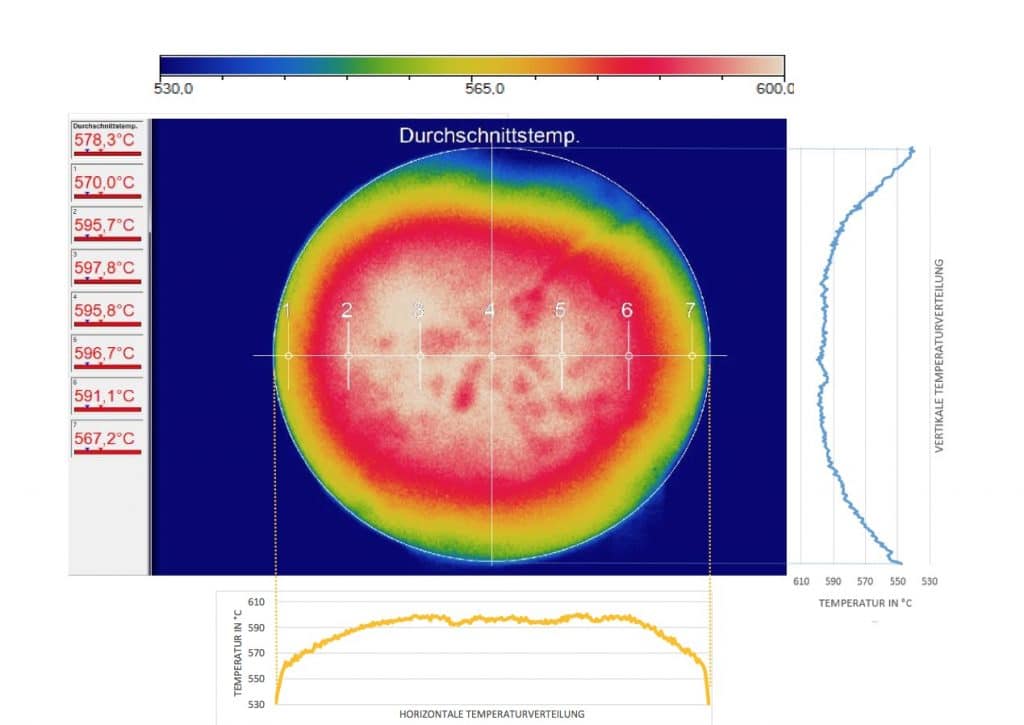

Thermal imaging camera detects hot spots and cold spots in the heating application

A thermal imaging camera is used whenever a high degree of measurement accuracy of the temperature distribution is required - because the development of individual heating applications is often a matter of millimetres and milliseconds. In addition to the FEM analysis, the thermal imaging camera can be used not only to simulate the temperature distribution, but also to map it in real time. The temperature of metal surfaces can thus be measured precisely without contact in the temperature range from 450°C to 1,800°C. The measuring accuracy is ±2 %.

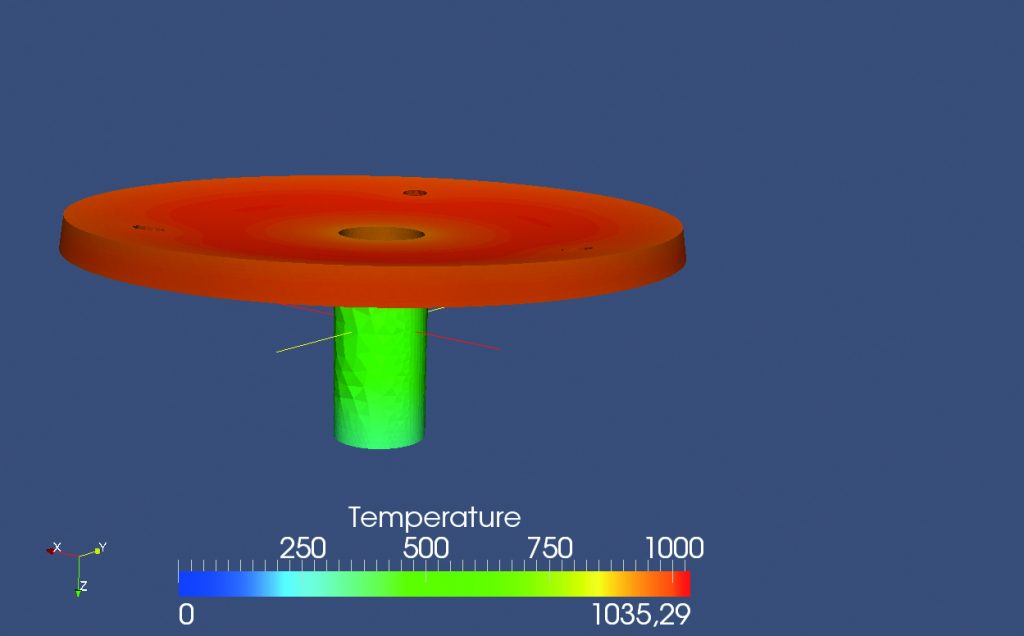

Simulate temperature distribution using FEM analysis

When developing customer-specific heating systems, designs can be put through their paces in theory in advance with the help of SolidWorks®. This allows the temperature distribution on components to be simulated at every stage of development, so that the designer can ensure that the desired temperature ranges are also achieved under realistic conditions. Further FEM calculations or strength calculations under the influence of temperature are also possible to ensure product safety.

Flame spraying for fixing heating conductors or for coating thermocouples

New: The ThermoExperts offer powder flame spraying - also known as metal spraying - as a spray coating process. It is used to attach mineral-insulated heating cable, for example with aluminum or stainless steel, while ensuring heat transfer. Advantage: In addition to the material savings, the main advantage is the possibility of mechanical post-processing to create a completely smooth surface in order to seal the component against a vacuum. However, flame spraying is also used to coat thermocouples. In this way, the service life of thermocouples in aggressive media such as fluoric acid or sulphuric acid can be extended.

The secret of ThermoExperts' success: highly qualified and loyal employees

The company was only founded in 2012. The managing directors then and now are Andreas Helf and Heiko Gevert. They have written a great success story in a very short space of time: they have always been able to meet the constantly growing demand for customer-specific, sheathed thermocouples and mineral-insulated heating cable with top quality. The company has grown accordingly - now with 16 employees. The highlight: the employees are loyal and faithful, i.e. the expertise and know-how remain within the company. Specialists are trained internally and further experts for thermal applications can be built up in this way. Thanks to the consistently high level of quality, the market has quickly gained confidence in the still relatively young company. And so, as the successes grow, so do the customer relationships with the absolutely reliable employees.

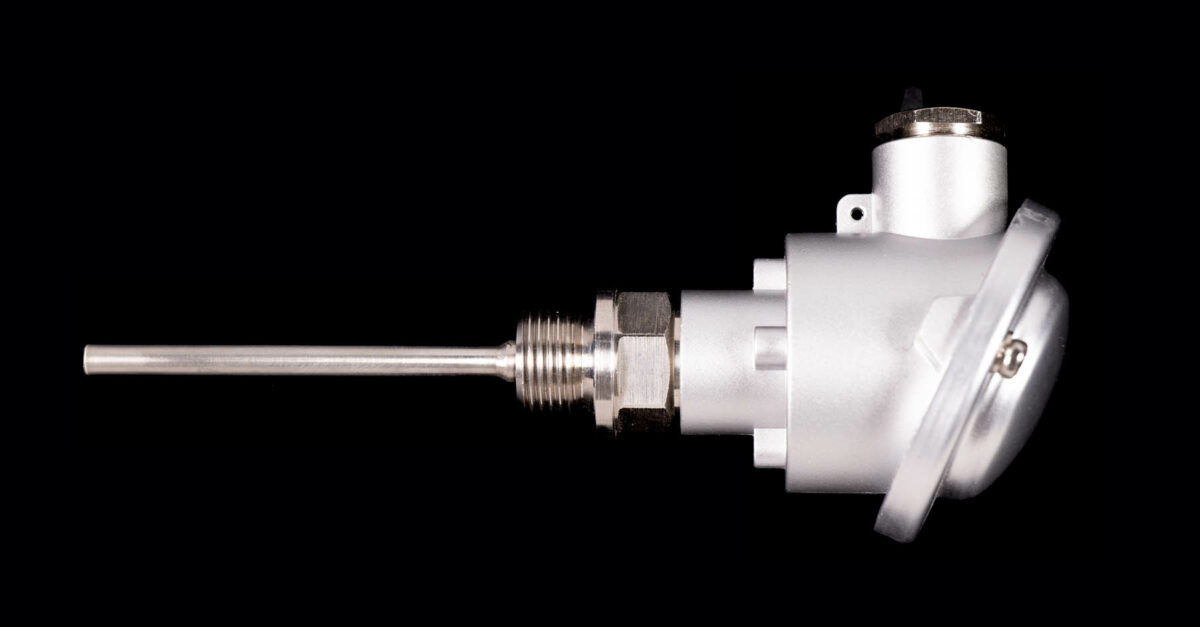

Trace heating for gas analysis

Customized solutions are the supreme discipline for the thermal experts. They recently received an inquiry from a gas manufacturer who needed a precise and constant temperature for its gas analysis. With clear specifications for the mass flow and pressure as well as the target temperature, a trace heating system had to be cleverly installed in a system with very limited space. Thanks to their experience and high-quality materials, the experts mastered this challenging task to the customer's complete satisfaction - because, in addition, the price-performance ratio and the deadlines were right.

Sheathed thermocouples with flattened measuring point

Sheathed thermocouples with a flattened measuring point (VMA/IMA) are required, for example, for temperature measurement on pumps and housings or on test benches - wherever temperatures need to be measured in gaps, on surfaces or at low installation heights. Typical applications are in mechanical engineering, the automotive industry and also in the research and development departments of universities and institutes.

The tip of the thermocouple with the measuring point is flattened in several production steps so that the contact surface of the thermocouple is enlarged. This facilitates fixing in the corresponding application and stabilizes the connection with a mechanical component.