With the measuring points, a distinction is made as to whether the two inner wires are tapered, insulated or welded to the sheath. Depending on the operating conditions, this can influence the response time. The choice is yours!

With the measuring points, a distinction is made as to whether the two inner wires are tapered, insulated or welded to the sheath. Depending on the operating conditions, this can influence the response time. The choice is yours!

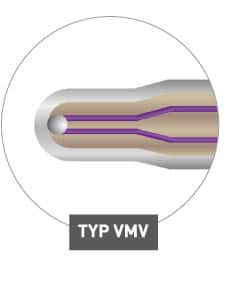

The outer diameter of the thermocouple can be reduced to a length of 50 mm at the measuring point. The reduction generally corresponds to half the original diameter. A reduction is possible up to a sheath diameter of 0.5 mm.

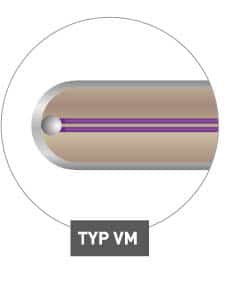

The ends of the thermocouple wires are welded to the sheath at the measuring point. The response times can thus be reduced by a quarter. The susceptibility to wear is increased as the insulation protection is reduced compared to the IM measuring point.

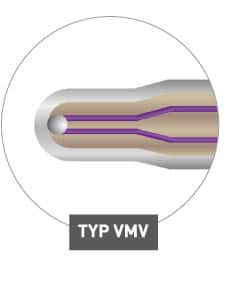

The outer diameter of the thermocouple can be reduced to a length of 50 mm at the measuring point. The measuring point is welded to the sheath. The reduction generally corresponds to half the original diameter. A reduction is possible up to a sheath diameter of 0.5 mm.

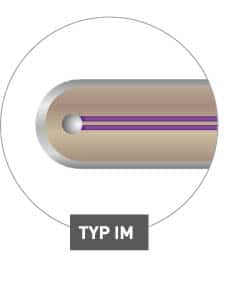

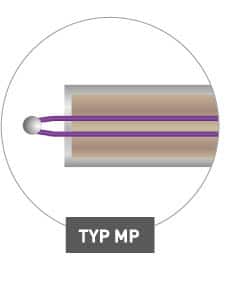

The measuring point is outside the sheath. The response time is therefore shorter. However, the measuring point is subject to greater wear and mechanical stress.